Table of Contents

Context: The Ministry of Environment has relaxed the norms related to Flue Gas Desulphurisation (FGD) systems for thermal power plants.

In 2015, India’s Environment Ministry mandated all 537 coal-fired plants to install FGD systems by 2018 to curb SO₂ emissions. Due to various challenges, the deadline has been extended to 2027-2029. 92% of India’s 600 coal-based power units are yet to install Flue Gas Desulphurisation (FGD).

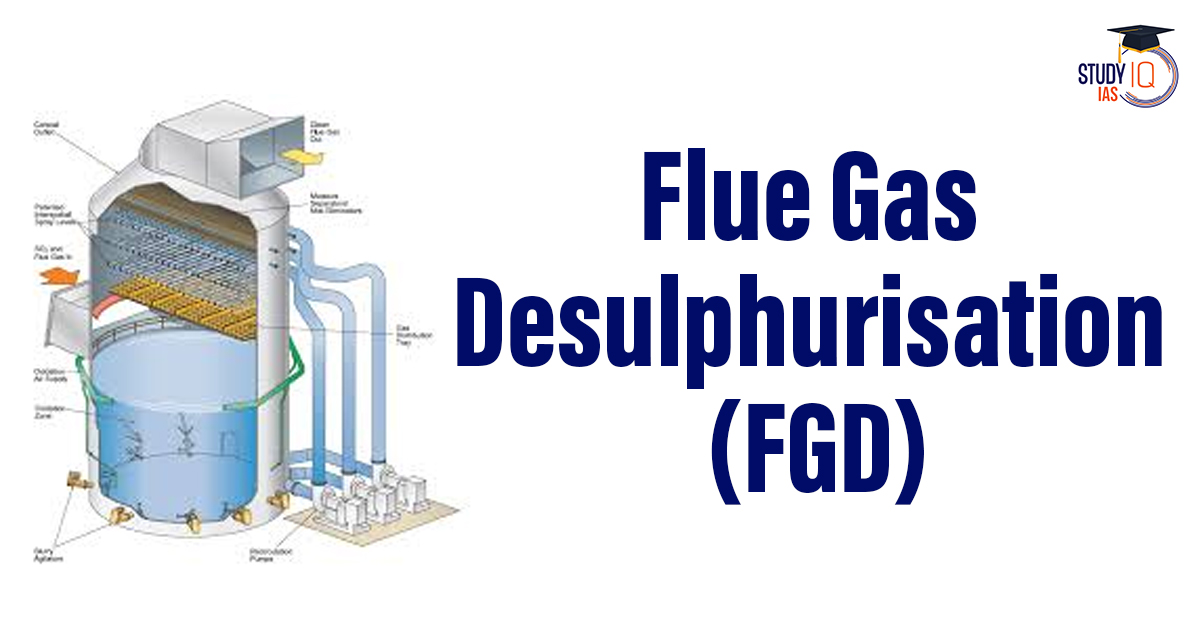

About Flue Gas Desulphurisation (FGD)

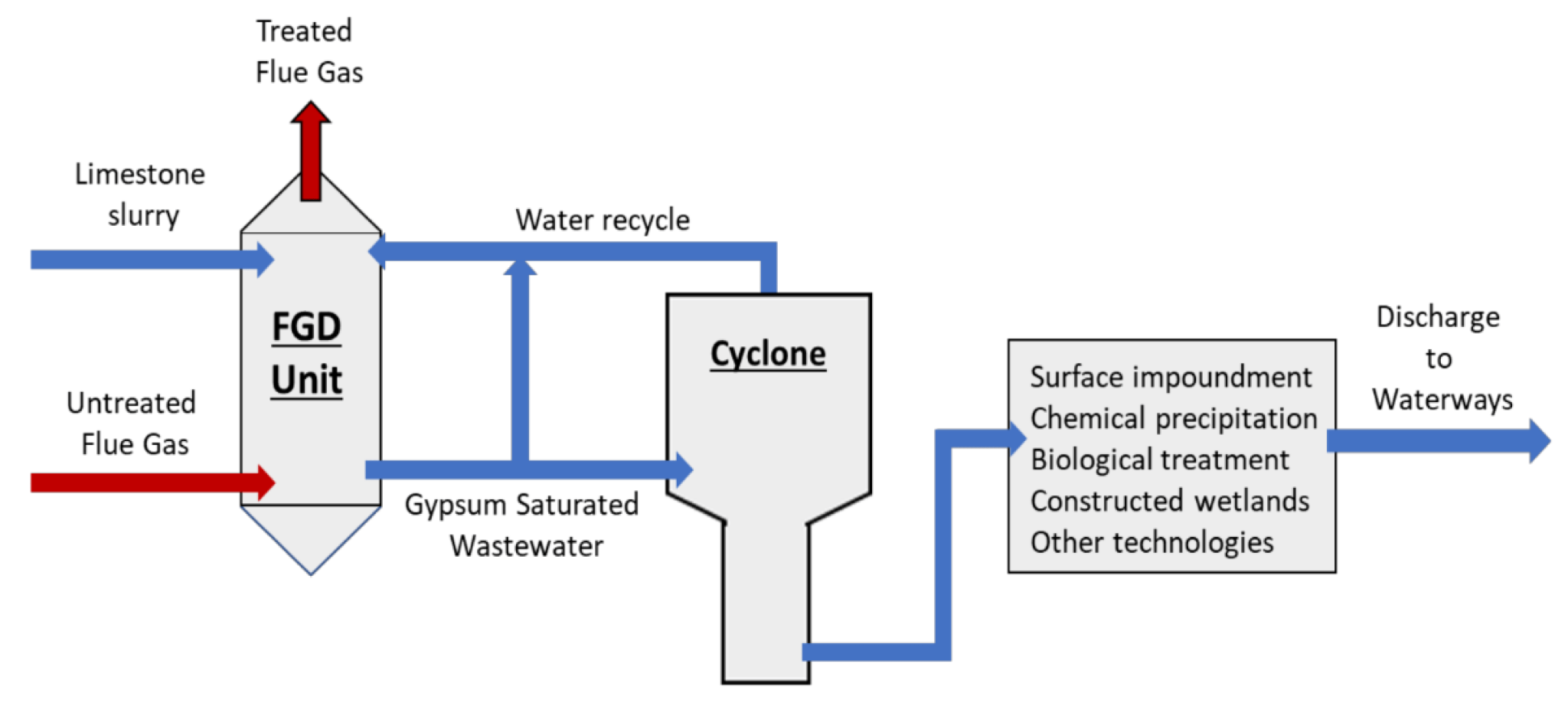

- Flue Gas Desulphurisation (FGD) refers to a set of technologies designed to remove sulfur dioxide (SO₂) from the exhaust flue gases of fossil-fuel power plants and other industrial processes.

- The primary goal is to reduce SO₂ emissions, which contribute to acid rain and respiratory problems.

- It uses various methods such as Wet Scrubbing, Dry Scrubbing, etc.

Advantages of FGD

- It can remove up to 90% or more of SO₂ from flue gases.

- The gypsum (byproduct) produced can be used in the construction industry, reducing waste.

- It helps power plants meet stringent environmental regulations regarding SO₂ emissions.

Challenge

- FGD systems are capital-intensive, with significant maintenance requirements.

- Wet FGD systems require excess water, which can be a concern in water-scarce regions.

Rationale Behind Eased FGD Norms for Thermal Power Plants

- Declining Sulphur Dioxide (SO₂) Levels: India has witnessed a decline in ambient SO₂ concentrations.

- In a 2023 assessment across 492 cities, only two (Dehradun and Kolar) exceeded the SO₂ limit.

- India’s annual SO₂ standard (50 µg/m³) is stricter than countries like Japan (66), the EU (52.4), and Australia (66).

- Limited Role of SO₂ in PM2.5 Health Impacts: Scientific studies indicate that SO₂ is not a major contributor to 5 pollution, which is more harmful to health.

- Cities with and without FGD units show no significant difference in SO₂ levels, suggesting marginal public health benefits.

- High Financial and Environmental Costs: The cost of installing FGD is high: ₹1.2 crore per MW, totalling approximately ₹2.54 lakh crore for all plants.

- The Ministry argued this would lead to only marginal improvements in PM2.5 levels, making it a disproportionate investment.

- Composition of Indian Coal: Indian coal has low sulphur content (0.5%) but high ash content, which naturally results in lower SO₂ emissions compared to other countries.

- Targeted Regulation: Under the new policy, only 22% of thermal plants (mostly near cities with historically poor air quality) must install FGDs.

- This targeted approach focuses on high-impact zones, improving cost-effectiveness without compromising environmental priorities.

Key Findings of the NIAS Study

The Office of the Principal Scientific Adviser, along with the National Institute of Advanced Studies (NIAS), Bengaluru, recently commissioned a study.

Findings of the Study

- 92% of coal used in Indian plants has low sulfur content (0.3%-0.5%), reducing the necessity for Flue Gas Desulphurisation (FGD).

- Only 8% of plants have installed FGDs, with 230 in various stages of installation and 260 yet to place orders.

- FGD installation costs are estimated at ₹1.2 crore per MW

Recommendations

- Flue Gas Desulphurisation (FGD) installation should be limited to plants using imported coal or coal with sulfur content above 0.5%.

- The focus should shift to controlling particulate matter (PM) emissions, which are detrimental to air quality in India.

- Electrostatic precipitators, costing ₹25 lakh per MW, can reduce PM pollution by 99% and are more cost-effective than FGDs.

Data Related to FGD Installation in Indian Thermal Power Plants (TPPs)

- Total coal-based TPP units in India: ~600 units

- Units that have installed FGD systems: Only 8% (~48 units)

- Units yet to install FGDs: 92% (~552 units)

- Category A Plants (within 10 km of NCR or cities with 1 million+ population):

- Total: 66 plants

- Installed FGD: Only 14 plants

- Compliance deadline: By 2027

Species in News for UPSC Prelims 2026: C...

Species in News for UPSC Prelims 2026: C...

World Wetlands Day 2026: Theme, History,...

World Wetlands Day 2026: Theme, History,...

Geological Heritage Sites of India: Sign...

Geological Heritage Sites of India: Sign...