Table of Contents

Context: Scientists have reported in Science that addressing solid-state battery (SSB) failures might depend on applying well-established mechanical principles.

Pesky Failure in Solid-State Batteries (SSBs)

The failure was due to lithium dendrites forming on the anode and piercing the solid electrolyte, which ultimately short-circuited the battery.

Key Contributing Factors

- Metal fatigue and mechanical stress are caused by repeated charge-discharge cycles.

- Cracks and voids are forming at the anode-electrolyte interface.

- Even low charge-discharge rates caused structural fatigue, breaking the electrolyte.

Also Read: Li-Ion vs Lead Acid Batteries

What are Solid State Batteries?

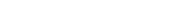

- Solid-state batteries are next-generation batteries that use a solid electrolyte instead of the liquid or gel electrolyte found in conventional lithium-ion batteries.

Structure and Working Principle

Components

- Anode: Often made of lithium metal, which allows for higher energy storage.

- Cathode: Made from various materials, similar to those used in lithium-ion batteries (e.g., lithium cobalt oxide, lithium nickel cobalt aluminium oxide).

- Solid Electrolyte: The key differentiator, made from ceramics, glass, sulfides, or solid polymers, separating the anode and cathode and allowing only ions to pass through.

Operation

- During discharge, lithium ions move from the anode to the cathode through the solid electrolyte, while electrons flow through the external circuit, powering the device.

- During charging, the process reverses: lithium ions travel back from the cathode to the anode

Advantages

- Higher energy density → Longer range for electric vehicles.

- Faster charging → E.g., 15-minute fast charge capability.

- Improved safety → Eliminates risk of leaks and thermal runaway.

- Compact design → Enables smaller and lighter battery packs.

Advanced Air Defence Radars: Types, Comp...

Advanced Air Defence Radars: Types, Comp...

Ion Chromatography, Working and Applicat...

Ion Chromatography, Working and Applicat...

Broadly Neutralising Antibodies (bNAbs):...

Broadly Neutralising Antibodies (bNAbs):...