Table of Contents

Context: Recently, China recalled 300 skilled engineers from Foxconn’s iPhone manufacturing in India and restricted rare earths, equipment, and skilled training.

Possible Reasons Behind Recalling 300 Chinese Engineers

- Curtail Technology Transfer: Prevent Indian manufacturing units — particularly in high-value electronics like iPhones — from acquiring the specialised know-how these engineers possess (production line setup, optimisation, troubleshooting).

- Delay India’s Manufacturing Take-off: Slow down India’s ambition to become a competitive electronics manufacturing hub.

- Maintain Supply Chain Dependence: Ensure India remains reliant on Chinese inputs, equipment, and rare earth materials.

- Preserve Chinese Economic Hegemony: Block potential competitors to safeguard Beijing’s dominant position in Asia’s manufacturing and export markets.

- Leverage Domestic Economic Pressures: China’s slowing economy, ageing population, and overcapacity make protecting export revenues crucial. Neutralising emerging rivals is part of its survival strategy.

How India Can Be Impacted

- Short-term operational disruption: Loss of skilled engineers will slow down production ramp-ups, delay projects, and increase dependence on foreign (often Chinese) technical support.

- Higher costs & slower growth: Alternative sources for inputs and equipment are more expensive and less efficient, increasing Capex/Opex for Indian firms.

- Global supply chain hesitation: Companies may hesitate to shift production from China to India, fearing instability and inefficiency.

- Persistent trade imbalance: Electronics imports (42% from China) and the $60 billion trade deficit in electronics could worsen before improving.

- Longer decoupling timeline: Achieving self-reliance in electronics could take 5–7 years, even with aggressive policy support.

What India Can Do

- High-level coordination: Create a PMO-led inter-ministerial task force (similar to the 2019 PLI committee) to handle supply chain challenges across ministries and in close consultation with industry.

- Diversify supply sources: Build partnerships with Taiwan, Japan, South Korea, the US, and the EU for critical minerals, components, and manufacturing equipment.

- Strengthen domestic ecosystem: Invest in R&D, skill development, and infrastructure for electronics and component manufacturing, not just assembly.

- Accelerate PLI & allied policies: Expand production-linked incentives beyond smartphones to semiconductors, components, and high-tech manufacturing.

- Strategic stockpiling: Maintain reserves of critical inputs (rare earths, key components) to withstand supply disruptions.

- Global alliances: Work with Quad, Indo-Pacific Economic Framework for Prosperity (IPEF), and other like-minded partners to reduce dependence on China for high-tech inputs.

- Ease business bottlenecks: Cut bureaucratic delays, improve logistics, and address “higher disabilities” in costs to make India more attractive for global value chains.

Amendments to New Drugs and Clinical Tri...

Amendments to New Drugs and Clinical Tri...

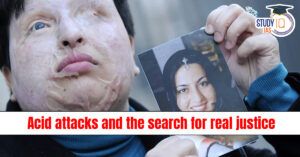

Acid Attacks and the Search for Real Jus...

Acid Attacks and the Search for Real Jus...

Doomsday Clock Reset to 85 Seconds to Mi...

Doomsday Clock Reset to 85 Seconds to Mi...